Horizon WES software provides “Overlapping Wave” order management in addition to wave and waveless to improve throughput, labor, and equipment utilization efficiencies.

Each of the three wave order management processes work well for specific businesses, applications, and order profiles. Horizon WES makes all three available as a standard feature to help organizations maximize their labor and equipment efficiencies to new levels.

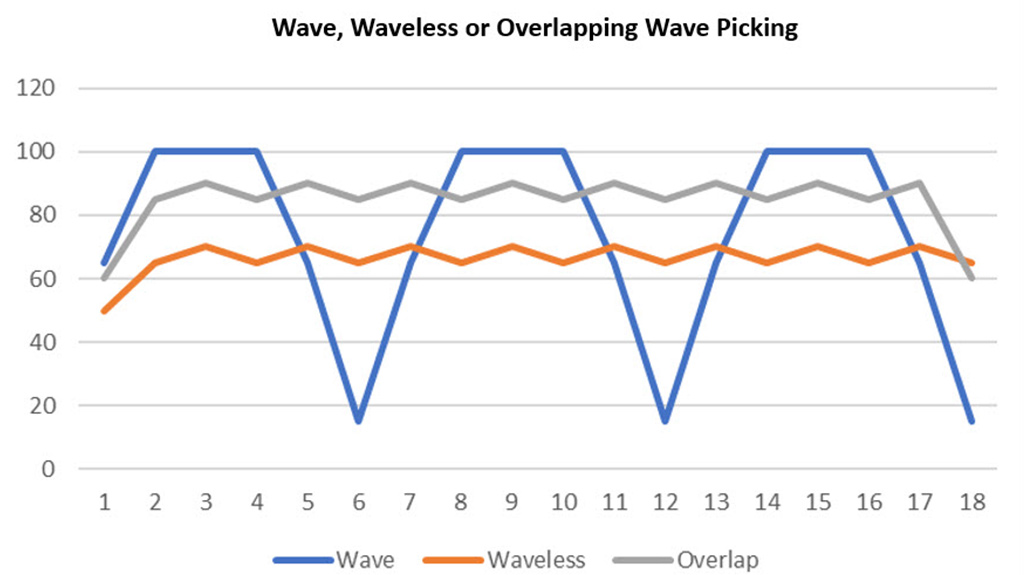

Wave picking consists of large batches of orders being processed once or twice per shift. To meet several hours fulfillment and same day shipping requirements, waveless order picking was introduced several years back. Waveless picking increases efficiencies because there are more orders to pick and optimize. As the wave is being built and completed it becomes less efficient.

Overlapping waves allow the first wave to reach its peak. As the wave begins to become less productive, the system introduces the second wave (over lapping). This keeps the entire system at a higher level of productivity and reduces labor and improves equipment utilization.

Looking at the chart, wave picking (blue) illustrates the periods of high productivity, but it also has valleys of low picking productivity as the wave is completed. The waveless picking (orange) evens out the peaks and valleys but provides a lower total throughput. Overlapping waves (grey) illustrates how this hybrid keeps productivity at the higher level of performance than just waveless picking.

About New Dawn Supply Chain

New Dawn, a division of Conveyco Technologies a leading systems integrator for over 40 years, has worked with leading organizations to help them meet and exceed their customers operations and order fulfillment requirements. From solving issues to a fully integrated system, New Dawn can provide the solution. The Horizon Warehouse Execution Software is modular and highly configurable allowing organizations to meet their immediate needs and the flexibility to grow and change just like their business.