How a WES Can Augment Your WMS to Optimize Your Supply Chain

Many order fulfillment operations, warehouses, and distribution centers are limited by the fact that they rely upon legacy WMS software. This legacy warehouse management system (WMS) might be “home grown,” from a vendor no longer in business or supporting your version or simply an older version which the company hasn’t updated in years.

While it’s true that most operations will need a WMS, it’s a mistake to believe that such a system will by default address all your needs. Likewise, it can often be a costly mistake to try and force the WMS to perform functions that it wasn’t specifically designed to perform. Introducing custom code into a legacy WMS system isn’t just expensive; it also involves a certain level of risk. Even if the original WMS company provides these customizations, often it creates future support and performance issues.

The solution? Adding a WES into the mix will allow you to layer in additional functionality without introducing the same risk that comes with custom code, and typically at a much more affordable level of investment.

Should you be considering implementing a WES in your operation? Below we take a look at the role that the WES serves in the warehouse, as well as how it interacts and augments the WMS and the benefits that it brings.

The Role of the WES in Your Warehouse

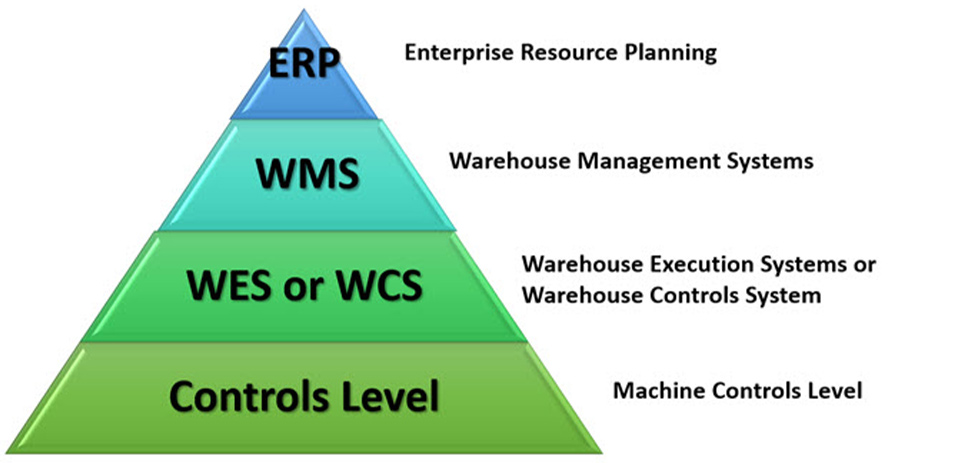

A warehouse execution system (WES) is at its heart the next stage in the evolution of the warehouse control system (WCS). As such, it starts with the same general level of functionality as the historic WCS but builds upon that baseline by providing much more. The result is that the WES is able to synchronize all layers of automation and activity within the warehouse in order to increase accuracy and efficiency both within and between zones and the four walls.

In many ways, the WES can be thought of as something like a conductor or lieutenant in your operation, orchestrating and directing all moving entities within the warehouse. Forklifts, manual pickers, automated picking equipment, order and wave execution, conveyor/sortation routing, print and apply, packing, shipping—all of this is controlled by the WES in a way that simply is not possible with only a WMS or with a more basic WCS.

How the WES Builds Upon the WMS

The WMS is primarily responsible for two key functions: Managing the flow of inventory throughout a facility (this has historically meant everything from receiving to putaway, replenishment, and shipping) and interfacing with the ERP to communicate with the rest of the business software.

With this in mind, most legacy WMS systems are capable of performing functions like transportation management, management reporting, supply chain integration, labor management, receiving, reserve putaway, shipping management, and yard management.

The WES, by comparison, is focused largely on orchestrating and balancing resources within a facility in order to optimize performance. As such, layering in a WES provides an operation with a means of adding additional functionality such as: Wave and order management, bin-level inventory management, manifesting, picking management (paper slip, RF scanner, voice, pick-to-light, pick label, etc.), system routing, QC/QA management, packing station management, and print-and-apply management.

Occasionally, the WES and WMS may overlap in some application capabilities, such as in labor management, receiving, reserve putaway, shipping management, and yard management. This allows the users to decide which program’s capabilities best meet their business requirements, processes and customer’s needs. This is easily done.

The WMS is primarily responsible for two key functions: Managing the flow of inventory throughout a facility (this has historically meant everything from receiving to putaway, replenishment, and shipping) and interfacing with the ERP to communicate with the rest of the business software.

With this in mind, most legacy WMS systems are capable of performing functions like transportation management, management reporting, supply chain integration, labor management, receiving, reserve putaway, shipping management, and yard management.

The WES, by comparison, is focused largely on orchestrating and balancing resources within a facility to optimize performance. As such, layering in a WES provides an operation with a means of adding additional functionality such as: Wave and order management, bin-level inventory management, manifesting, picking management (paper slip, RF scanner, voice, pick-to-light, pick label, etc.), system routing, QC/QA management, packing station management, and print-and-apply management.

Occasionally, the WES and WMS may overlap in some application capabilities, such as in labor management, receiving, reserve putaway, shipping management, and yard management. This allows the users to decide which program’s capabilities best meet their business requirements, processes and customer’s needs. This is easily done.

Benefits of Leveraging a WES to Augment the WES

The benefit of leveraging a WES to build upon the WMS is two-fold.

First, if you have a legacy WMS (Think: Manhattan, High Jump, SAP, Softeon, Tecsys, Infor, etc.) and you find that your operation needs additional functionality outside of what your existing system provides, implementing a WES gives you a way of adding this functionality without the need for custom WMS development.

Because custom development on these legacy systems typically comes with a substantial level of investment (time and money), going the route of implementing a WES will often be more efficient. It also comes with less risk: While the WES will interface with the WMS, it does not replace it. This is significantly less risky than, say, completely replacing your legacy WMS with a new solution, or introducing custom code to that mission-critical system. The end result is that you should be able to extend the life of your WMS significantly.

Second, if you feel that you are currently “trapped” in a specific manufacturer’s ecosystem, implementing a manufacturer-agnostic WES can allow you to break out of that ecosystem. In the past, there were quite a few independent (non-manufacturer owned) WMS and WES companies. Today, many of the independents have been acquired by the material handling manufacturing companies. The software quickly evolved to support that manufacturer’s equipment trapping organizations into their company ecosystem or organizations deciding to keep running an orphan or legacy system.

To freely evaluate and decide on which technologies, brands, and models of new equipment you can leverage in your operation, you need to have the freedom of choice that a manufacturer-agnostic WES provider allows.

When is implementing a WES the right move?

- To add additional functionality that your WMS does not currently support.

- Escape the ecosystem and utilize equipment and manufacturers equipment your current WMS provider will not support.

- To add functionality to a “fragile” WMS.

- Wanting additional processes, reports, and general support that your current WMS provider can’t, doesn’t, or is too costly to provide.

- Escaping the need to shutdown and restart your system to avoid or come back from crashes.

- Not wanting to through the time, pain, and resources of changing your existing WMS.

A trusted software provider can help you understand your options and guide you to the solution that makes the most sense for your business. Contact us today to speak with a member of the New Dawn Team.